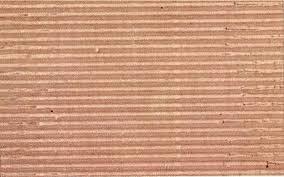

Paper Corrugated Board

Price 500 INR/ Piece

Paper Corrugated Board Specification

- Paper Type

- Corrugated Board

- Pulp Material

- Wood Pulp

- Pulp Type

- Unbleached

- Style

- Single Wall

- Size

- Customized

- Thickness

- 3 mm to 7 mm

- Tightness

- High

- Width

- Standard and Custom

- Substance

- High Strength

- Bursting

- Good (meets packaging grade standards)

- Color

- Brown

- Compatible Printing

- Offset, Screen, and Flexo Printing

- Usage

- Packaging, Carton Box Making

- Odor

- Odorless

- Edge Crush Test (ECT)

- 23-35 kN/m depending on quality

- Recyclability

- 100% Recyclable

- Surface Finish

- Smooth

- Flute Type

- A, B, C, E or combination (as specified)

- Moisture Content

- Below 8%

- Lead Time

- 7-10 days

- Surface Texture

- Uniform fiber distribution

- Printing Surface

- High Ink Absorption

- Caliper Tolerance

- ±0.1 mm

Paper Corrugated Board Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Supply Ability

- 50000 Pieces Per Week

- Delivery Time

- 1 Week

- Packaging Details

- Paper box packing available.

- Main Domestic Market

- Delhi

About Paper Corrugated Board

Owing to our one year of expertise in this market, we have been able to provide a broad range of Paper Corrugated Board. The offered board is well suited for making cartons and corrugated boxes that are used for packing fragile goods for safe transportation. The provided board is manufactured using quality checked corrugated rolls and ultra-modern techniques. This Paper Corrugated Board is immensely praised in industries and shops due to its good stacking property.

Features:

- Lightweight

- Easy to carry

- Recyclable

- High load bearing capacity

Superior Performance and Durability

Our corrugated boards meet premium packaging standards, providing high bursting strength and excellent edge crush resistance. Meticulously engineered for tightness and substance, they deliver reliable protection for goods during transit and storage, reducing the risk of damage.

Eco-Friendly and Fully Recyclable

Manufactured using unbleached wood pulp, our corrugated boards are 100% recyclable, supporting sustainable packaging solutions. Their eco-conscious composition makes them an ideal choice for businesses aiming to minimize environmental impact.

Tailored to Your Application

Available in standard and custom dimensions, our boards are adaptable for a wide variety of packaging needs. With customizable flutes, thickness, and width, they cater to both small and large-scale carton box manufacturing and printing requirements, ensuring a precise fit every time.

FAQs of Paper Corrugated Board:

Q: How can I customize the size and flute type for my corrugated board order?

A: You can specify your required dimensions and select preferred flute types (A, B, C, E, or combinations) when placing your order. Our production process accommodates custom sizes and flute arrangements to match your packaging needs.Q: What are the benefits of using unbleached, high-strength corrugated boards for packaging?

A: Unbleached, high-strength corrugated boards offer superior durability, strong edge crush (2335 kN/m), and bursting resistance. They provide excellent protection for contents, are eco-friendly, and support demanding packaging applications.Q: When can I expect delivery after confirming my requirements?

A: Orders for customized corrugated boards are typically ready for dispatch within 710 days from order confirmation, ensuring timely delivery and continuity in your packaging operations.Q: Where are these corrugated boards manufactured and supplied?

A: Our corrugated boards are manufactured in India and can be supplied to customers nationwide, catering to both regional and national packaging requirements.Q: What is the process for ensuring consistent caliper and uniform fiber distribution?

A: We use advanced production techniques to maintain a caliper tolerance of 0.1 mm and ensure even fiber distribution. Rigorous quality checks at each stage guarantee a smooth finish and reliable board characteristics.Q: How does the boards surface support various printing methods?

A: The high ink absorption surface is optimized for offset, screen, and flexo printing, delivering vivid and sharp print results, making the board suitable for branded packaging and display purposes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Corrugated Board Category

B Flute Corrugated Cardboard

Price 500 INR / Piece

Minimum Order Quantity : 1000 Pieces

Pulp Material : Mixed Pulp

Paper Type : Corrugated Paper

Style : Recycled

Color : Brown

G Flute Corrugated Cardboard

Price 500 INR / Piece

Minimum Order Quantity : 1000 Pieces

Pulp Material : Wood Pulp

Paper Type : Corrugated Paper

Style : Virgin

Color : Brown

|

RADIUS PACKAGING SOLUTION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry